HyperThreads, Bangalore, India

Team

Leonid Krykhtin

Katharina Heiger

Abdulmonem Assem

Fatemeh Ghasemi

Pranav Semwal

Katharina Heiger

Abdulmonem Assem

Fatemeh Ghasemi

Pranav Semwal

Workshop

HyperThreads-2011

Location

Bangalore, India

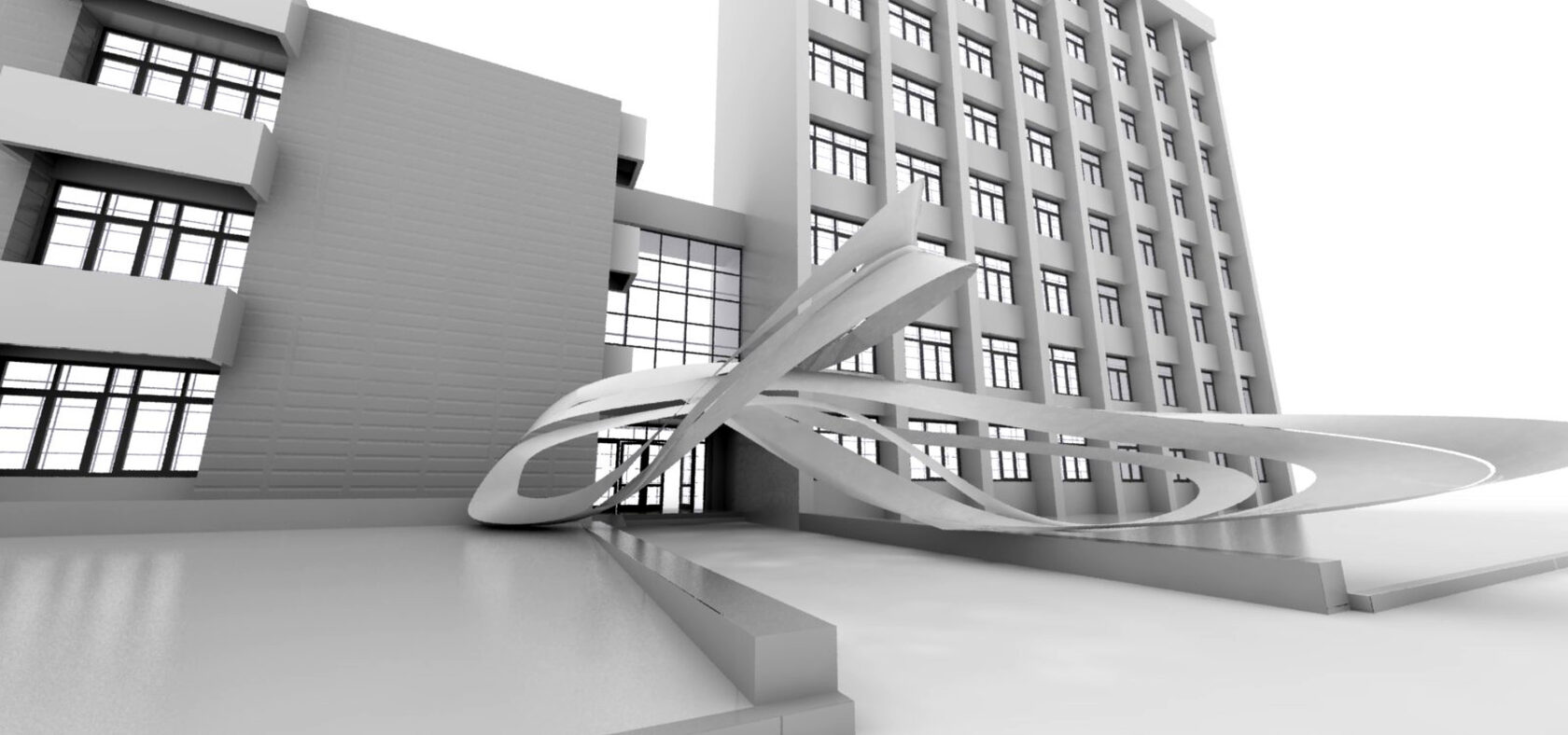

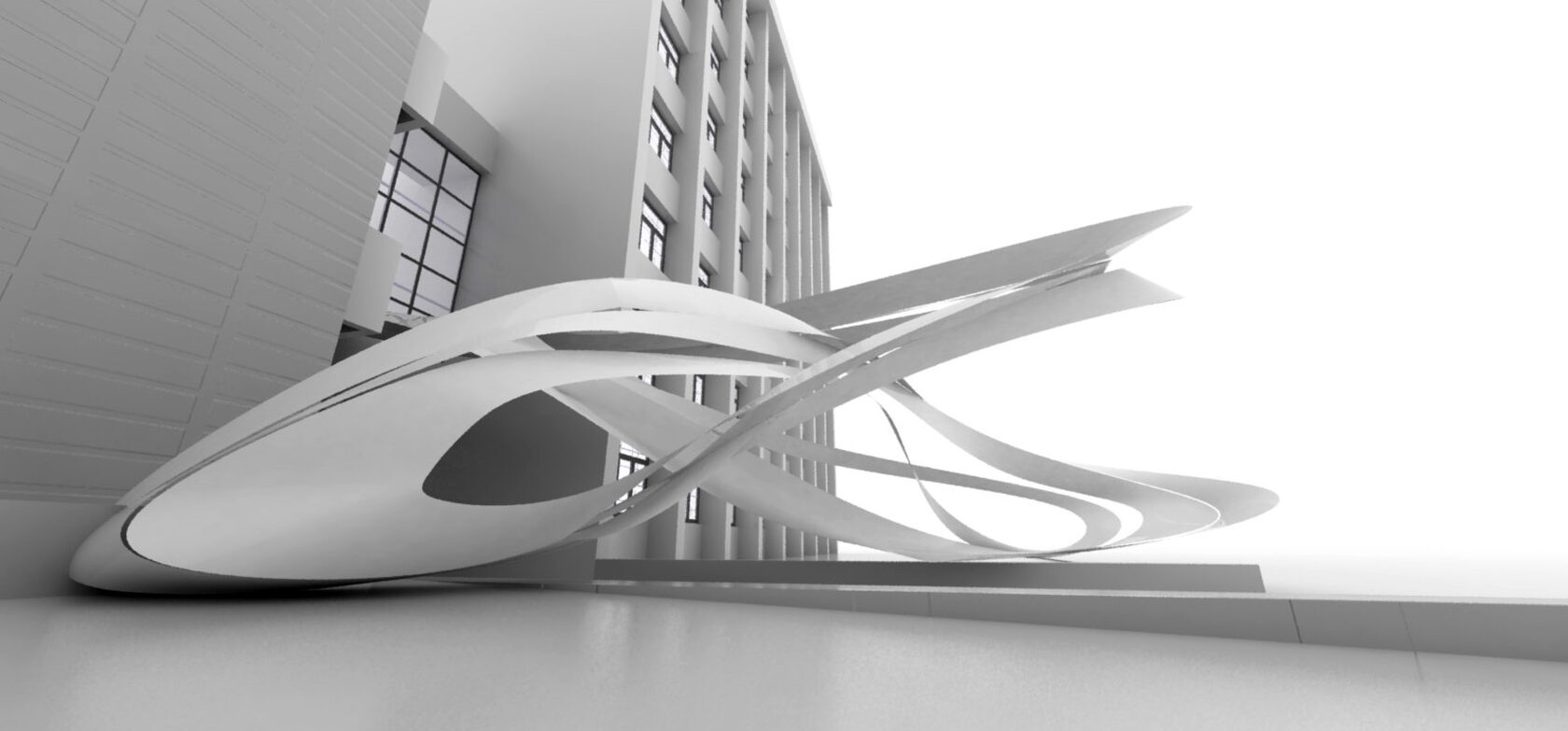

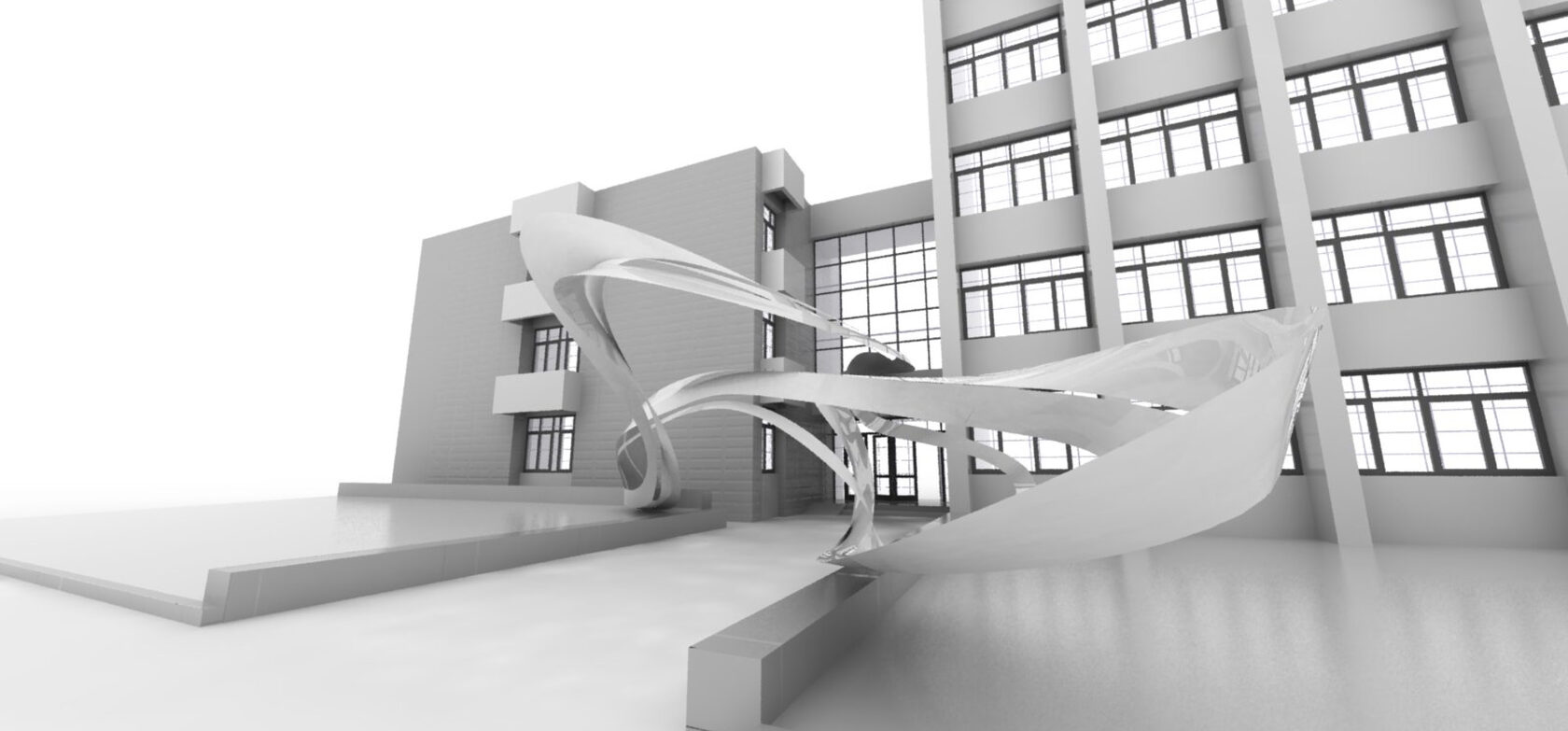

HyperThreads project explores architectural shell structures from computation and digital fabrication point of view. During 10 day workshop we had to research shell structures using digital computation tools such as Maya, Grasshopper and Algor, and generate formal studies by having a feedback loop between structural test results and Maya N-cloth simulated 3D formal catalogue.

After structurally optimised shell form was created, it was optimised using Grasshopper to create a buildable canopy installation using local construction materials and techniques.

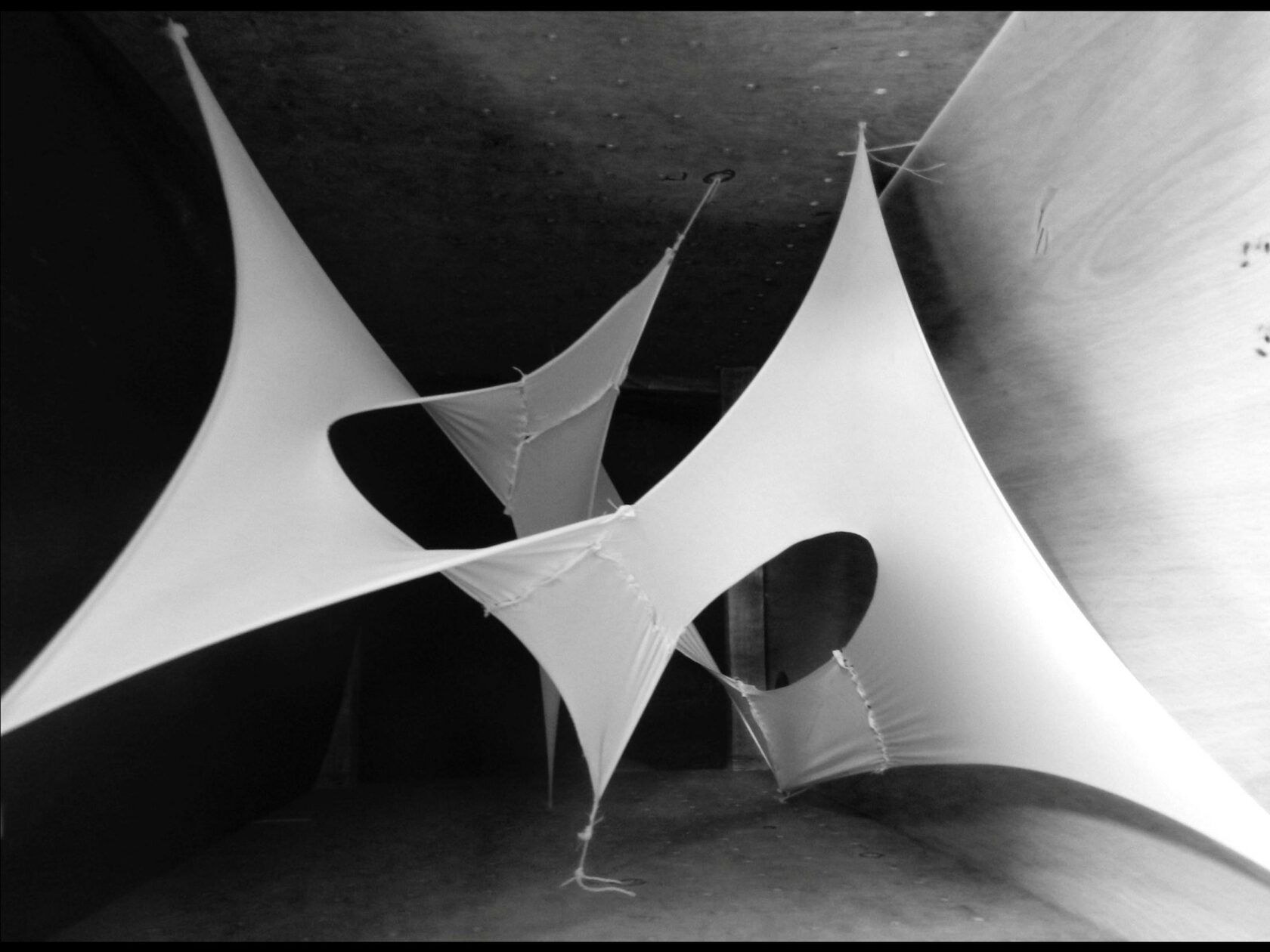

During this project apart from digital testing and experimentation it was coupled with physical testing using lycra stretching fabric, wire and tape. The physical testing was essential to see the difference and similarity between digitally simulated shell and physically assembled small scale prototype.

At the end of the project a real concrete shell canopy was erected in 1:1 scale at the entrance of local Bangalore architecture institute using local construction team and structural engineer.

After structurally optimised shell form was created, it was optimised using Grasshopper to create a buildable canopy installation using local construction materials and techniques.

During this project apart from digital testing and experimentation it was coupled with physical testing using lycra stretching fabric, wire and tape. The physical testing was essential to see the difference and similarity between digitally simulated shell and physically assembled small scale prototype.

At the end of the project a real concrete shell canopy was erected in 1:1 scale at the entrance of local Bangalore architecture institute using local construction team and structural engineer.

HyperThreads, Bangalore, India

Team

Leonid Krykhtin

Katharina Heiger

Abdulmonem Assem

Fatemeh Ghasemi

Pranav Semwal

Katharina Heiger

Abdulmonem Assem

Fatemeh Ghasemi

Pranav Semwal

Workshop

HyperThreads-2011

Location

Bangalore, India

HyperThreads project explores architectural shell structures from computation and digital fabrication point of view. During 10 day workshop we had to research shell structures using digital computation tools such as Maya, Grasshopper and Algor, and generate formal studies by having a feedback loop between structural test results and Maya N-cloth simulated 3D formal catalogue.

After structurally optimised shell form was created, it was optimised using Grasshopper to create a buildable canopy installation using local construction materials and techniques.

During this project apart from digital testing and experimentation it was coupled with physical testing using lycra stretching fabric, wire and tape. The physical testing was essential to see the difference and similarity between digitally simulated shell and physically assembled small scale prototype.

After structurally optimised shell form was created, it was optimised using Grasshopper to create a buildable canopy installation using local construction materials and techniques.

During this project apart from digital testing and experimentation it was coupled with physical testing using lycra stretching fabric, wire and tape. The physical testing was essential to see the difference and similarity between digitally simulated shell and physically assembled small scale prototype.

At the end of the project a real concrete shell canopy was erected in 1:1 scale at the entrance of local Bangalore architecture institute using local construction team and structural engineer.